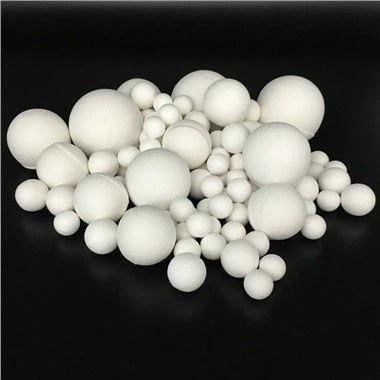

92% Ceramic Aluminum Ball

Delivery term:The date of payment from buyers deliver within days-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Shandong

-

Validity to:

Long-term effective

-

Last update:

2023-11-13 19:52

-

Browse the number:

390

+

- Contactaixin:

Contactaixin:

taocimaoyi(Mr.)

-

Email:

telephone:

phone:

-

Area:

Shandong

Address:News Paper Building, No.286 Liuquan Road, Gaoxin District, Zibo, Shandong, China

- Website:

+

â– Description:

The selection of alumina grinding balls depends on the required processing effect and material characteristics. Different products have different particle sizes, shapes, and hardness. Coarse grinding balls are suitable for quickly removing large defects on the material surface, while finer grinding balls can be used to achieve higher smoothness and accuracy.

When using ceramic grinding media, it is usually necessary to place them in a grinding machine or polishing equipment, combined with appropriate grinding agents and lubricants. It generates friction and impact with the surface of the workpiece under the rotation of the equipment, thereby achieving the effect of grinding or polishing.

Â

â– Specific:

|

Shaping method |

AB92 |

|

Pressing Method |

φ30/40/50/60/70mm |

|

Rolling Method |

φ10-50mm |

|

Item |

AB92 |

|

Al2O3(%) |

≥92 |

|

ZrO2(%) |

0 |

|

Bulk Density(g/cm3 |

≥3.60 |

|

Water Absorption(%) |

<0.01 |

|

Abrasion Loss(‰) |

≤0.15 |

|

Mohs' Hardness |

9 |

|

Color |

White |

Remark: Regular size range from Dia.10 Dia.20 Dia.30 Dia.40 Dia.45 Dia.50 Dia.60 Dia.70.

Bigger size like Dia.80 Dia.90 Dia.100 are available upon requests

Â

â– Packaging:

25kg net in PP-bag or big bag of 500 or 1000kg net. 20-24MT/20' FCL.

Â

â– Key benefits:

â— Extremely cost effective

â— Improves grinding efficiency and energy costs

â— Longer service time due to low wear rate

â— Contamination-free to the color and composition of the ground material

Â

â– Application:

Â

In the production of ceramic floor tiles, ceramic medias are widely used in grinding and polishing processes. They can help you achieve efficient, accurate, and consistent grinding results, improving the surface finish and quality of floor tiles. In addition, it can also be used to trim and polish the edges and corners of floor tiles, ensuring the overall consistency and aesthetics of the product

It’s not affected by most chemicals, is non-conductive, non-magnetic, and chip-resistant.

Â

In general ,inert alumina ceramic ball is not susceptible to chemical reactions, and its inherently dense texture, very low water absorption, does not act as a drying agent.

But they are widely used in petroleum, chemical, fertilizer, natural gas and environmental protection industries as a covering support material and tower packing for catalysts in the reactor.

Â

Most of them are bottom-filling materials such as chemical fiber plant, alkylbenzene plant, aromatics plant and other hydrocracking refining equipment, catalytic reforming equipment, isomerization equipment, and demethylation equipment.

Â

http://www.zbshell.com/